Inside the Atelier: Crafting Bespoke Luxury Car Interiors

From Coachbuilt Heritage to Modern Cabins

Journeys That Began in Saddlers’ Workshops

Before dashboards gleamed with veneers, interiors were the domain of saddlers shaping comfort for long journeys. Stories from family ateliers reveal patterns passed down, from waxed thread recipes to pressure-tested lacing methods, influencing how seats embrace, bolster, and breathe on spirited drives and relaxed commutes alike.

When Hand Tools Meet Laser Precision

Modern shops map complex geometries with scanners, yet final perfection still belongs to blades, bone folders, and patient fingertips. A single misaligned stitch can disturb reflections across a sweeping door card, so artisans blend measured data with felt intuition to resolve that final, satisfying click when panels align.

A Commission That Changed Expectations

One client requested a stitched horizon line that wrapped continuously from the dash into the rear quarter panels. It required new jigs, altered foam densities, and countless test pieces, yet the result made silence feel larger, turning every morning commute into a composed, private exhibition of restraint.

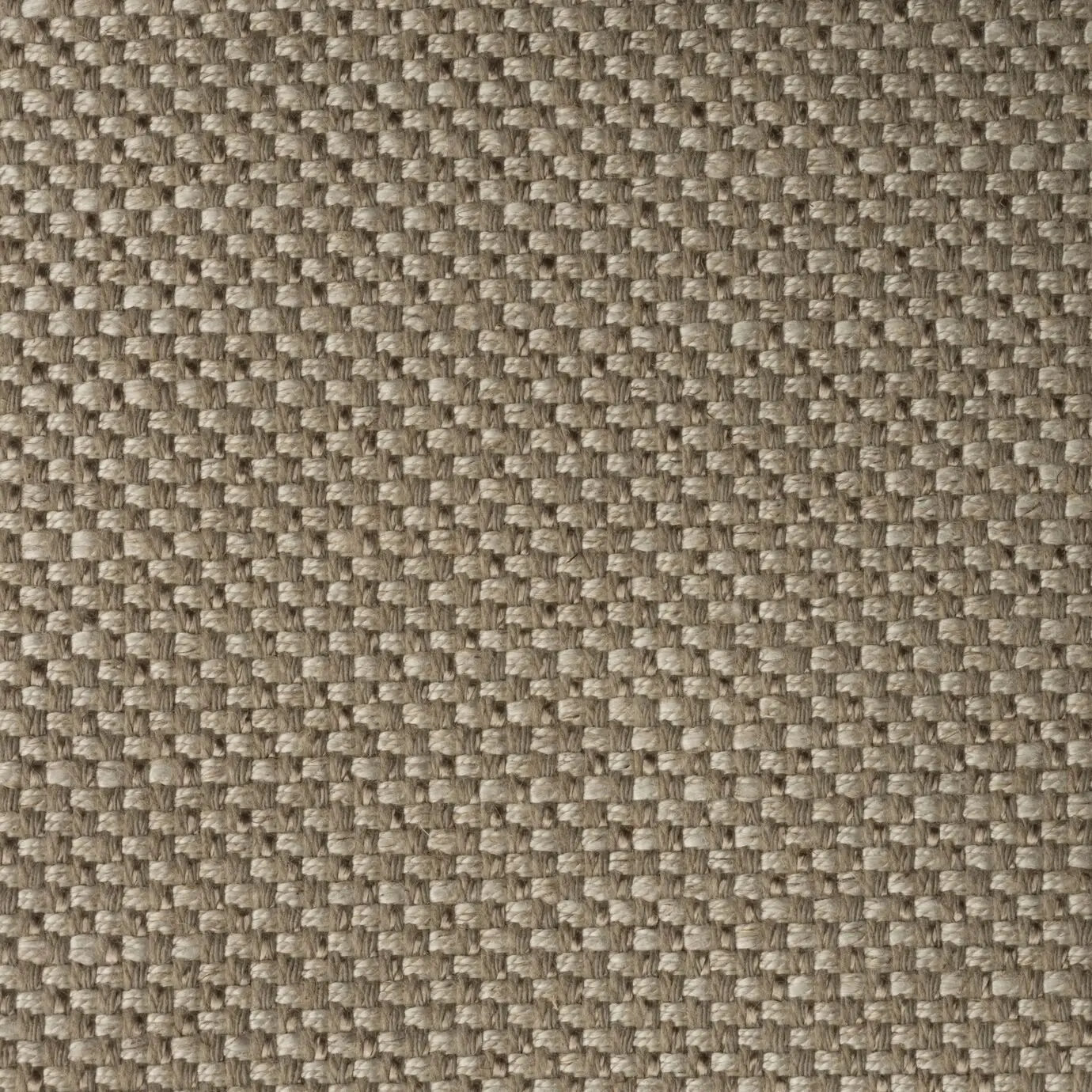

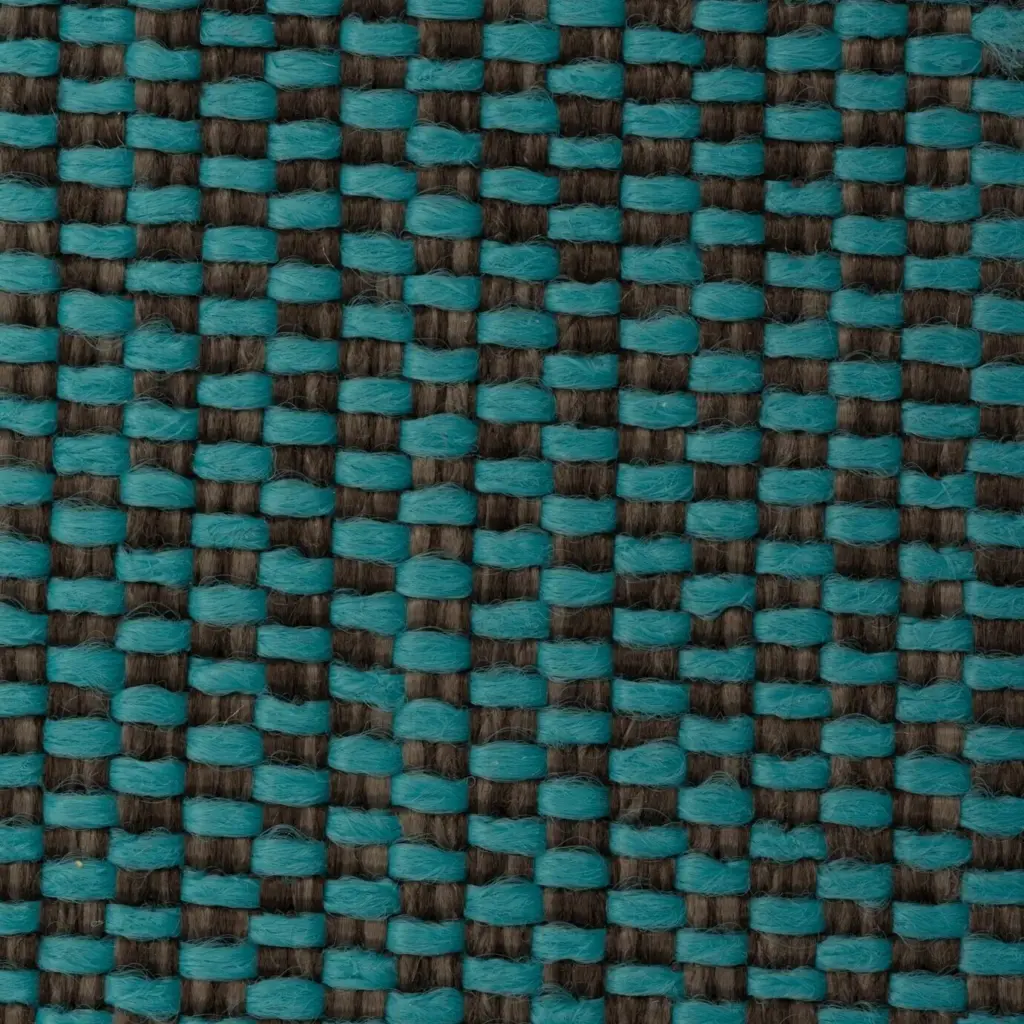

Leather Without Compromise

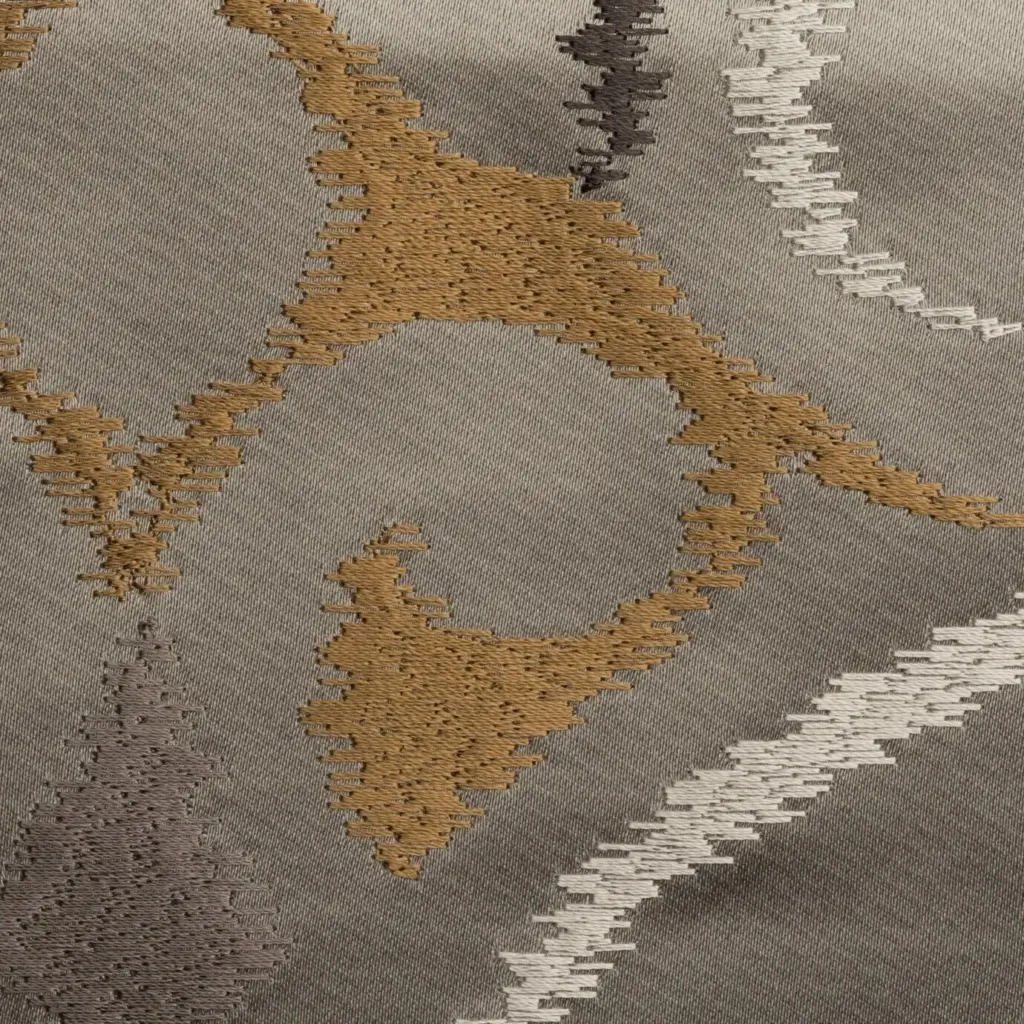

Stitchwork That Speaks

Wood, Veneers, and Marquetry

Metals, Knurling, and Bespoke Touchpoints

Engine-Turned Patterns with Depth

Guilloché, or engine turning, creates repeating reflections that soften glare while signaling crafted intent. Machinists index each pass to maintain cadence, then seal the surface to resist fingerprints. The effect is hypnotic, like ripples on water, yet durable under constant contact and shifting cabin temperatures.

Knurling That Guides the Hand

Diamond, straight, or helical patterns each deliver different grip and visual tempo. Depth, pitch, and edge break choose how a dial feels between fingers. Done right, the hand navigates without looking, reinforcing confidence during driving while quietly elevating every interaction into a small, satisfying ritual.

Inlays That Catch the Light

Mother-of-pearl, enamel, or finely brushed steel can be set within wood or leather to reward shifting perspectives. Placement matters; small accents near vents or handles punctuate movement. When the cabin brightens at dawn, these notes sparkle briefly, then recede, respecting composure and long-haul comfort.

Commission Process: From Vision to Cabin

Caring for Craft and Ensuring Longevity

Routine Care that Respects Material

Travel and Storage Considerations

All Rights Reserved.